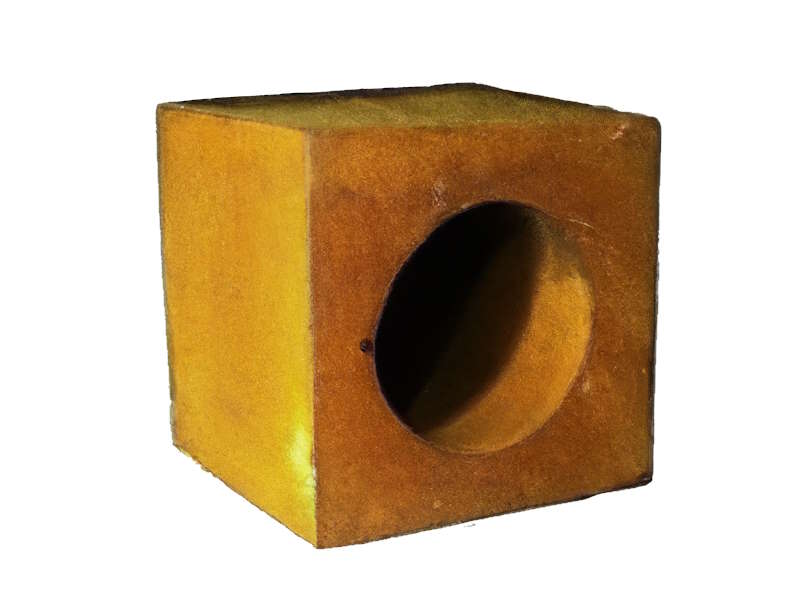

Burner Block

A burner block is a crucial component used in industrial furnaces and heating equipment. It is typically made from refractory ceramic material to withstand high temperatures and harsh conditions during operation. The primary function of the burner block is to provide a stable and efficient platform for the burner assembly. It plays a vital role in distributing heat evenly and directing the flame towards the desired area, ensuring optimal heat transfer and combustion efficiency. To prevent cracking due to thermal shock, high-quality burner blocks are engineered to handle temperature fluctuations effectively, making them essential for reliable and safe industrial processes.

Uses of Burner Block:-

Stability and Support: The primary function of the burner block is to provide a stable and secure platform for the burner assembly. It ensures that the burner remains in its designated position during operation, preventing any misalignment or movement that could impact performance.

Heat Distribution: The burner block helps in distributing heat evenly within the furnace or heating equipment. By directing the flame and controlling its trajectory, the burner block ensures uniform heat distribution across the targeted area, promoting efficient heat transfer.

Optimal Combustion: The design of the burner block plays a crucial role in promoting optimal combustion. It ensures that the flame is directed towards the desired area, maximizing the efficiency of the combustion process and minimizing heat loss.

Thermal Protection: Burner blocks are made from refractory ceramic materials with high thermal resistance. They can withstand the intense heat generated by burners, providing thermal insulation and protecting surrounding structures from heat damage.

Resisting Thermal Shock: High-quality burner blocks are engineered to handle rapid temperature fluctuations without cracking or deforming. Their ability to resist thermal shock ensures their longevity and reliability in demanding industrial environments.

Reduction of Flue Gas Emissions: Properly designed burner blocks help in achieving better combustion control, which can lead to reduced flue gas emissions and improved environmental performance.

Energy Efficiency: By ensuring efficient heat distribution and combustion, burner blocks contribute to overall energy efficiency in industrial heating processes, reducing fuel consumption and operating costs.

Safety: A well-maintained burner block enhances the safety of the industrial furnace or heating system. It prevents potential burner misfires or flame instability that could lead to accidents or operational issues.

Overall, the burner block is a critical component that optimizes the performance, efficiency, and safety of industrial furnaces, boilers, and other heating equipment used in various industries such as steel, metallurgy, glass, ceramics, petrochemicals, and more.