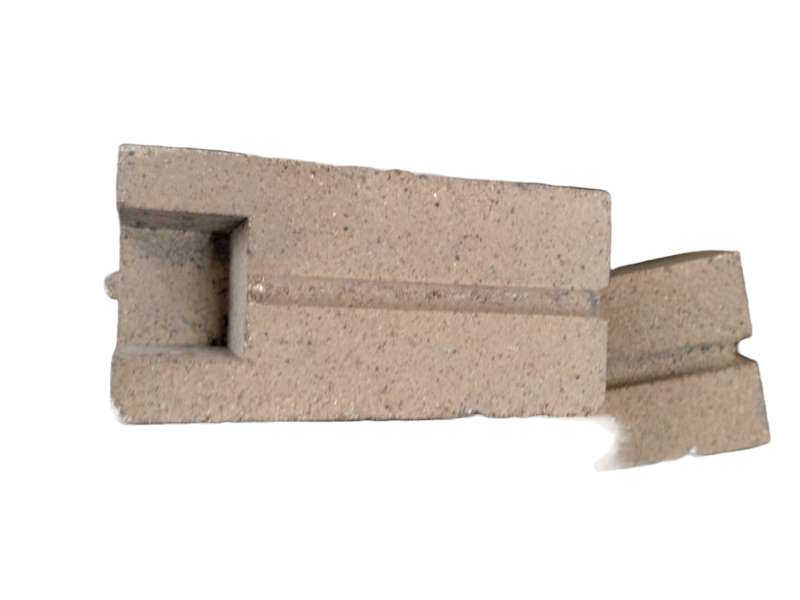

Refractory Blocks

Refractory blocks are specialized building blocks made from refractory materials designed to withstand high temperatures and harsh conditions. These blocks are crucial components in various industrial applications, including furnaces, kilns, and reactors. They provide insulation and protection to the surrounding structures, ensuring efficient and safe operations. One notable advantage of refractory blocks is their availability in different sizes, offering versatility and adaptability to various equipment and industrial settings. The availability of various sizes allows for precise fitting and lining, making them an essential choice for constructing fire-resistant structures and withstanding extreme temperatures.

Uses of Refractory Blocks:-

Furnace Lining: Refractory blocks are widely used to line the inner walls of industrial furnaces, providing insulation and protection against extreme temperatures, ensuring efficient heat containment and transfer.

Kiln Lining: In industries such as ceramics and cement, refractory blocks are employed to line kilns, ensuring uniform heating and maintaining stable temperatures for optimal material processing.

Boiler Lining: Refractory blocks are used to line boilers in power plants and industrial facilities, providing insulation and resistance to high-temperature combustion gases for boiler efficiency.

Incinerators: Refractory blocks are crucial in waste incinerators, where they line the combustion chambers to withstand high-temperature combustion and resist chemical reactions with waste materials.

Foundries: Refractory blocks are used in foundries for furnace linings and molds, providing the necessary thermal insulation and withstanding the high temperatures during metal casting.

Glass Industry: Refractory blocks are used in glass furnaces and tanks, where they line the structures to withstand extremely high temperatures during glass melting.

Coke Ovens: In the steel industry, refractory blocks are employed to line coke ovens, providing thermal insulation during the coking process.

Petrochemical Industry: Refractory blocks are used in various units of refineries and petrochemical plants to handle high-temperature processes and resist chemical attacks.

Heat Treatment Furnaces: Refractory blocks are used in heat treatment furnaces for annealing, hardening, and tempering processes, providing stable thermal insulation.

Power Generation: Refractory blocks are utilized in power generation facilities to line gasifiers, incinerators, and other high-temperature equipment.

Metal Smelting: In metal smelting processes, refractory blocks are used to line furnaces and crucibles, providing heat resistance and protection against metal corrosion.

Chemical Processing: Refractory blocks are used in chemical processing equipment such as reactors and vessels, providing resistance to chemical corrosion and thermal stress.

These are just a few examples of the diverse uses of refractory blocks across various industries. Their ability to withstand high temperatures and harsh environments makes them indispensable for ensuring reliable and efficient industrial processes.